Product Title

Factory Direct: Single-Mode ADSS Aerial Fiber Optic Cable with Aramid Yarn Strength Member

What is ADSS Cable?

ADSS (All-Dielectric Self-Supporting) cable is a fully non-metallic fiber optic cable engineered for aerial installation on utility poles and transmission lines. Its dielectric construction allows safe deployment in high-voltage environments without grounding or messenger wires. This makes it a cost-effective and low-maintenance alternative to OPGW and OPAC cables, especially for power utilities and telecom operators seeking reliable, long-distance communication links.

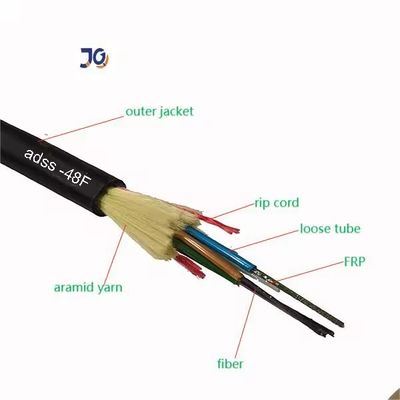

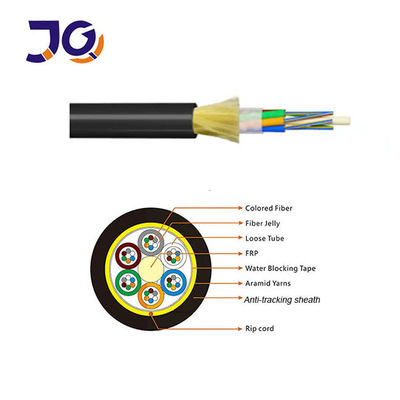

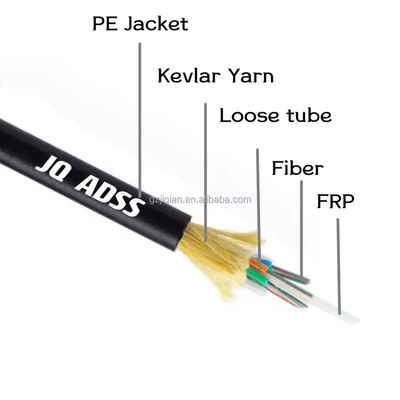

Structure & Design

• Stranded Loose Tube Design – Optical fibers are contained within gel-filled loose tubes for water blocking and mechanical stability.

• Central FRP Strength Member – Provides core rigidity and minimizes cable deformation under tension.

• Aramid Yarn Reinforcement – Delivers high tensile strength, allowing longer spans and better resistance to wind and ice loads.

• Dual Sheath Options – Available in PE (Polyethylene) for standard applications or AT (Anti-Tracking) for installations near high-voltage lines, preventing electrical tracking.

• UV-Resistant & Weatherproof – Designed to withstand sunlight, rain, snow, and temperature fluctuations.

Key Features

-

Dielectric & Safe: Fully non-metallic design eliminates risk of short circuits, making it ideal for live-line installation.

-

Self-Supporting: No need for messenger wires or additional supports, reducing installation cost and time.

-

High Mechanical Strength: Aramid yarn reinforcement ensures excellent performance under tensile loads, wind, and ice conditions.

-

Durability: Resistant to UV radiation, moisture, chemicals, and extreme weather, ensuring long service life.

-

Stable Transmission: Maintains low attenuation and signal integrity even under mechanical stress or temperature changes.

-

Customizable: Fiber counts, sheath material, and span length can be tailored to meet specific project requirements.

Applications

-

PE Sheath: Recommended for power line routes below 110kV where standard mechanical protection is sufficient.

-

AT Sheath: Designed for power lines ≥110kV, providing anti-tracking protection in high electric field environments.

-

Ideal for telecommunication backbones, utility communication systems, smart grid projects, and rural broadband deployment.

-

Suitable for both short- and long-span installations (up to 1500m depending on configuration).

Standards & Compliance

• Manufactured in full compliance with IEEE P1222, IEC 60794-1, and other international standards for optical fiber cable.

• 100% optical and mechanical testing before shipment to ensure performance and reliability.

• ISO9001/ROHS certified production process.

Additional Benefits

• Lower Total Cost of Ownership: No need for grounding or separate support wires reduces installation and maintenance costs.

• Future-Proof Design: High fiber count options allow network expansion without replacing cables.

• Flexible Packaging: Supplied on wooden or steel reels with moisture-proof wrapping for safe transportation and storage.

Structure and Technical Specifications

1. ADSS single jacket

| fiber count |

structure |

fiber per tube |

losse tube diameter

(MM)

|

FRP/pad diameter (mm) |

Thickness of outer jacket(mm) |

Ref. Outer

Diameter

(mm) |

Ref. Weight

(kg/km) |

| PE Jacket |

AT Jacket |

| 4 |

1+5 |

4 |

1.9 |

2.0/2.0 |

1.7±0.1 |

9.8 |

80 |

90 |

| 6 |

1+5 |

6 |

1.9 |

2.0/2.0 |

1.7±0.1 |

9.8 |

80 |

90 |

| 8 |

1+5 |

4 |

1.9 |

2.0/2.0 |

1.7±0.1 |

9.8 |

80 |

90 |

| 12 |

1+5 |

6 |

1.9 |

2.0/2.0 |

1.7±0.1 |

9.8 |

80 |

90 |

| 24 |

1+5 |

6 |

2.0 |

2.0/2.0 |

1.7±0.1 |

9.8 |

85 |

95 |

| 48 |

1+5 |

12 |

2.0 |

2.0/2.0 |

1.7±0.1 |

10.0 |

88 |

98 |

| 72 |

1+6 |

12 |

2.2 |

2.0/2.0 |

1.7±0.1 |

10.5 |

98 |

108 |

| 96 |

1+8 |

12 |

2.2 |

2.0/3.4 |

1.7±0.1 |

12.0 |

122 |

135 |

| 144 |

1+12 |

12 |

2.2 |

3.0/7.2 |

1.7±0.1 |

15.2 |

176 |

189 |

Tips: all the specifications in the abolve table is approximate data, for more detals specifications,

pls contact our salers.

2. ADSS double jacket

| fiber count |

structure |

fiber per tube |

losse tube diameter

(MM)

|

FRP/pad diameter (mm) |

Thickness of outer jacket(mm) |

Ref. Outer

Diameter

(mm) |

Ref. Weight

(kg/km) |

| PE Jacket |

AT Jacket |

| 4 |

1+5 |

4 |

1.9 |

2.0/2.0 |

1.7±0.1 |

12.0 |

125 |

135 |

| 6 |

1+5 |

6 |

1.9 |

2.0/2.0 |

1.7±0.1 |

12.0 |

125 |

135 |

| 8 |

1+5 |

4 |

1.9 |

2.0/2.0 |

1.7±0.1 |

12.0 |

125 |

135 |

| 12 |

1+5 |

6 |

1.9 |

2.0/2.0 |

1.7±0.1 |

12.0 |

125 |

135 |

| 24 |

1+5 |

6 |

2.0 |

2.0/2.0 |

1.7±0.1 |

12.0 |

128 |

138 |

| 48 |

1+5 |

12 |

2.0 |

2.0/2.0 |

1.7±0.1 |

12.5 |

130 |

140 |

| 72 |

1+6 |

12 |

2.2 |

2.0/2.0 |

1.7±0.1 |

13.2 |

145 |

155 |

| 96 |

1+8 |

12 |

2.2 |

2.0/3.4 |

1.7±0.1 |

14.5 |

185 |

195 |

| 144 |

1+12 |

12 |

2.2 |

3.0/7.2 |

1.7±0.1 |

16.5 |

212 |

228 |

Tips: all the specifications in the abolve table is approximate data, for more detals specifications,

pls contact our salers.

|

Fiber type

|

Attenuation

(+20℃)

|

Bandwidth

|

Optical cable cut-off wavelength

|

|

@850nm

|

@1300nm

|

@1310nm

|

@1550nm

|

@850nm

|

@1300nm

|

| G.652 |

--- |

--- |

≤0.36dB/km |

≤0.22dB/km |

--- |

--- |

≤1260nm |

| G.655 |

--- |

--- |

≤0.40dB/km |

≤0.23dB/km |

--- |

--- |

≤1450nm |

| 50/125µm |

≤3.3dB/km |

≤1.2dB/km |

--- |

--- |

≥500MHz·km |

≥500MHz·km |

--- |

| 62.5/125µm |

≤3.5dB/km |

≤1.2dB/km |

--- |

--- |

≥200MHz·km |

≥500MHz·km |

---

|

Details picture shows

single jacket ADSS fiber cable

double jacket ADSS fiber optic cable

Packing:

FAQ

Q1: Are you a manufacturer or trading company?

A: We are a direct manufacturer with over 10 years of experience specializing in fiber optic cables, FTTH drop cables, patch cords, and accessories. Our factory is located in Guangzhou, China, and we welcome on-site visits or video factory tours.

Q2: How do you ensure product quality?

A: Quality is our top priority. Every cable undergoes 100% optical and mechanical testing before shipment, including attenuation, tensile, and temperature cycle tests. After price confirmation, we offer free samples for performance verification.

Q3: Can I place a small or trial order?

A: Yes. We support small orders and pilot projects, helping customers test our products before bulk purchase.

Q4: What is your typical lead time?

A: Standard production time is 3–7 working days, depending on order quantity and customization. We work to ensure fast delivery and reliable logistics support.

Q5: Do you offer OEM and customization services?

A: Absolutely. We can print your logo, customize packaging, fiber counts, sheath color, and length to meet project-specific requirements.

Q6: Are your raw materials certified?

A: Yes. We use materials that comply with ISO9001, RoHS, and CE standards, guaranteeing stable quality and environmental compliance.

Q7: What is the warranty period?

A: Our products come with a 10-year warranty and lifetime technical support, ensuring long-term reliability.

Q8: Can you provide technical support for installation?

A: Yes. Our engineering team offers online guidance, installation manuals, and blowing parameter recommendations to support your project success.

Q9: Do you provide export documentation?

A: Yes. We supply CO (Certificate of Origin), CE, RoHS, and test reports to assist with customs clearance and compliance.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!